Loren Ipsum Loren Ipsum Loren Ipsum Loren Ipsum Loren Ipsum Loren Ipsum Loren Ipsum Loren Ipsum Loren Ipsum

Ramit

Various techniques are required when it comes to cutting anything from the finest capillaries to the most solid rods. Whether by hand or with a machine, using a laser or a blade: the application must be appropriate to requirements. Because the cutting edges are just as different as the method used to create them.

Score cutting and breaking

Score cutting is actually quite simple: the surface of the glass is slightly damaged, with a groove cut into the glass in a process known as scoring. This serves as the breaking point. Subjected to bending stress and possibly a slight pull, the glass will then break.

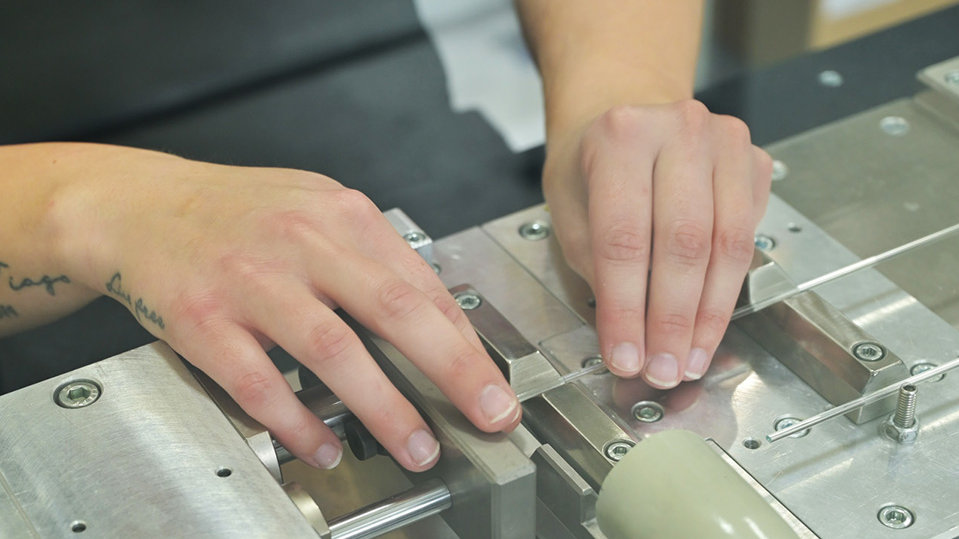

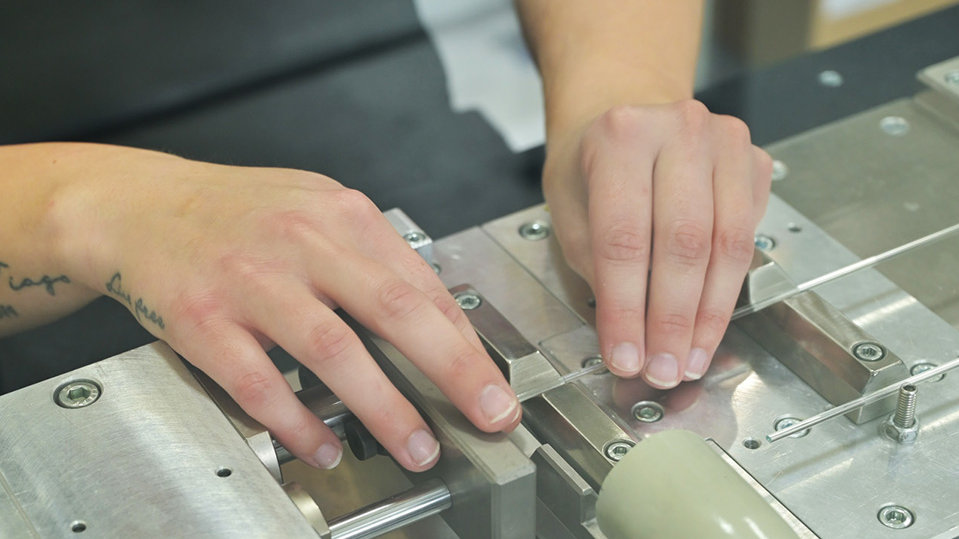

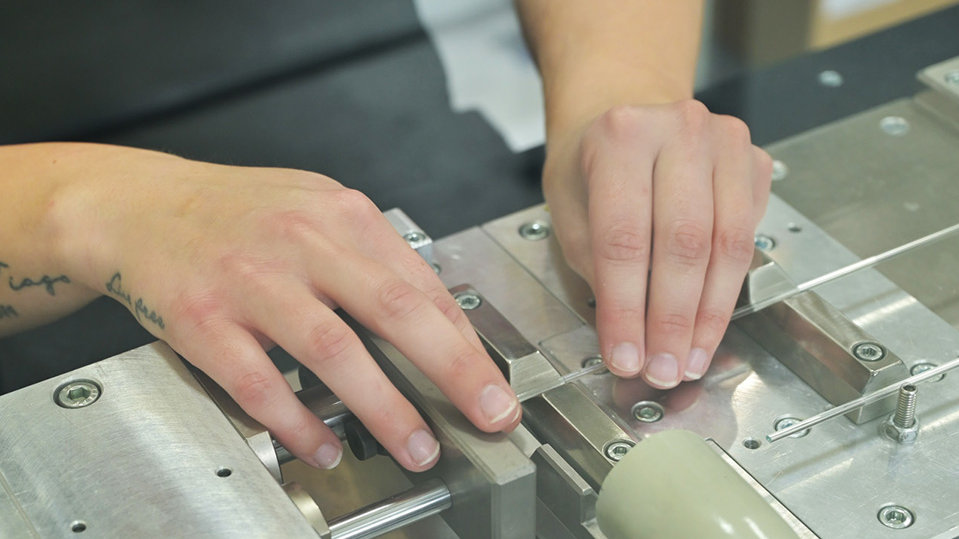

Manual score cutting

Manual score cutting

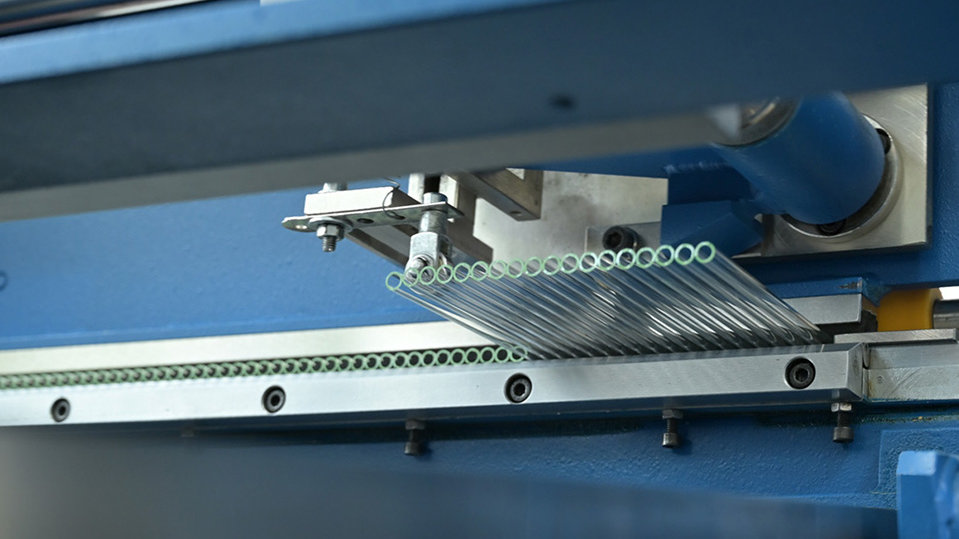

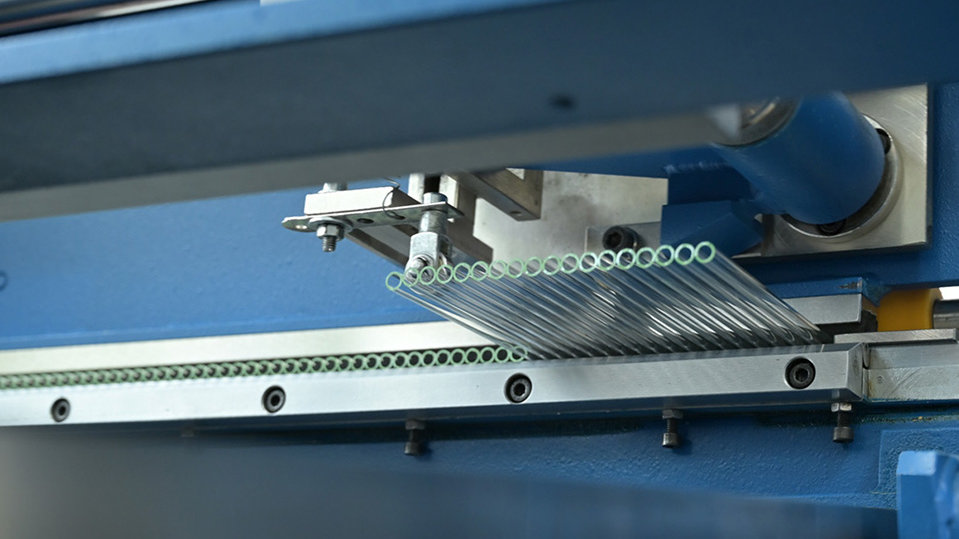

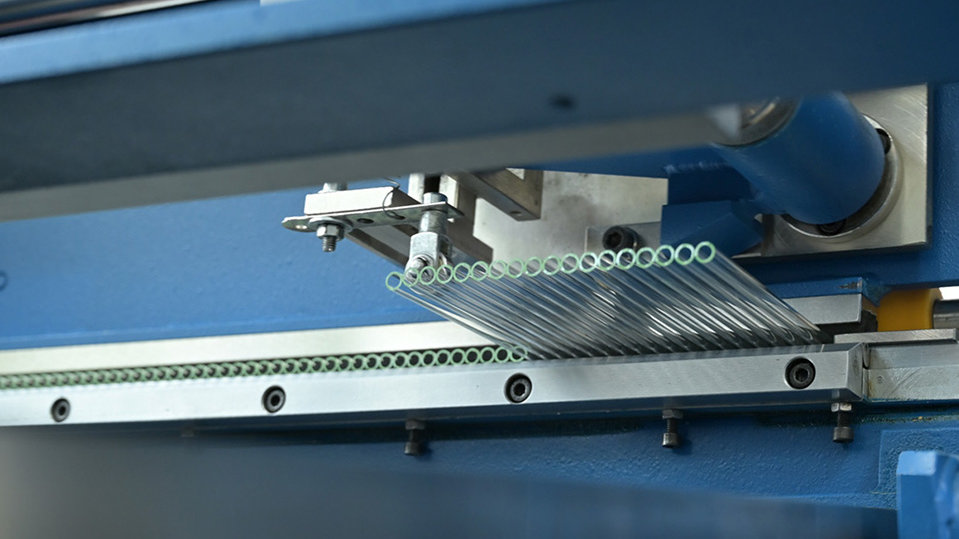

Automatic score cutting

Automatic score cutting

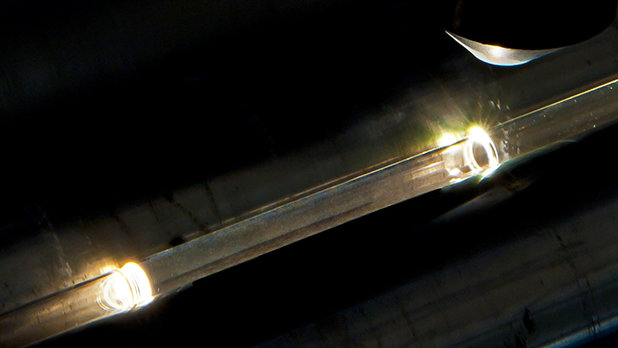

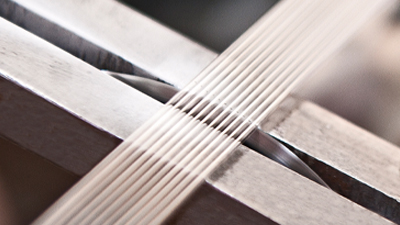

360° circular score cutting

Circular score cutting is the procedure used to create particularly flat cutting edges on tubes and capillaries, without the need for grinding. The score required to break the glass is made to the glass surface with a circular motion. The resulting notch ensures a clean break and prevents any chipping or protrusions on the cut surface. The 360° rotation also leaves a cutting edge that is very slightly beveled.

Manual score cutting

Manual score cutting

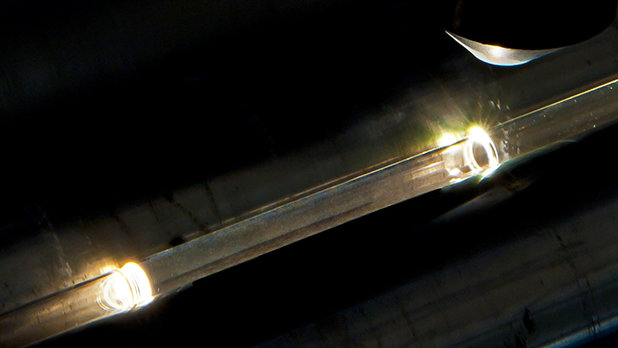

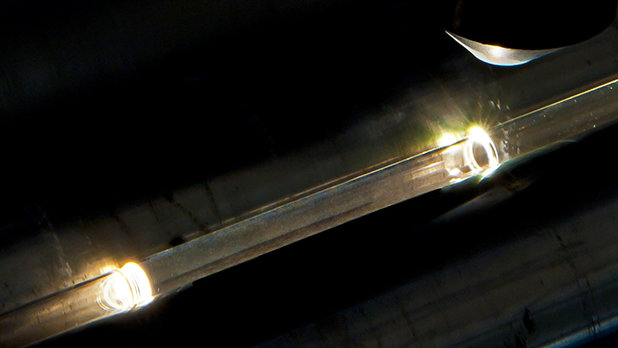

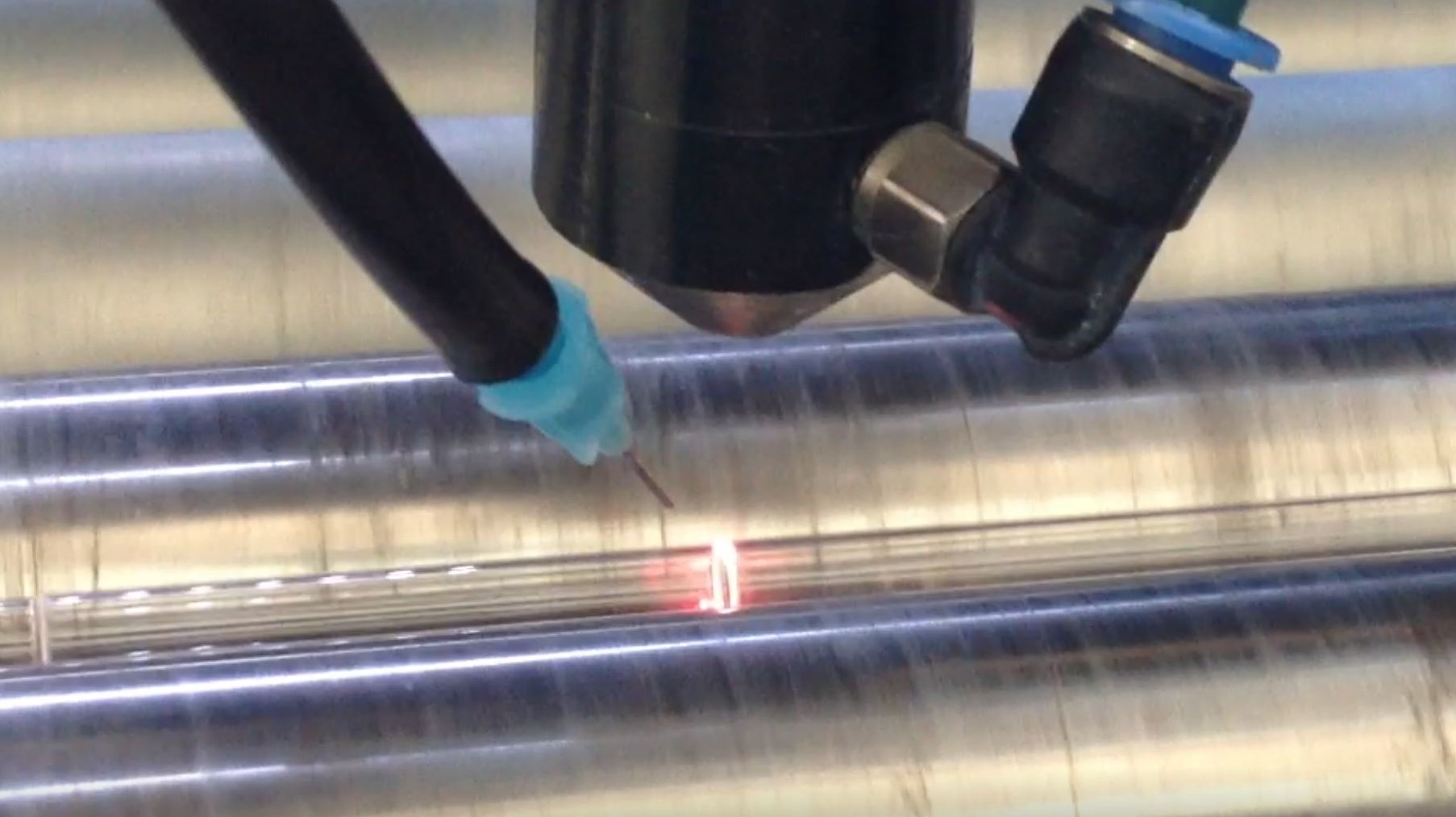

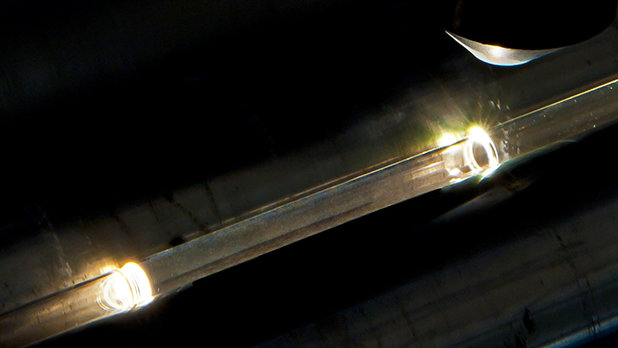

Laser cutting including laser thermal shock cracking

Laser sublimation cutting involves vaporizing the glass with a laser. Air is constantly circulated around the tubes, largely preventing condensation from forming on the glass. To separate the parts, a targeted stream of air is applied to the cutting slit in order to further support the break.

Just like the conventional thermal shock cracking procedure, there is also a localized heating of the component, before it cracks due to the rapid cooling and resulting “thermal shock”. The use of a laser for thermal cracking can be advantageous for some types of glass, as the application of heat is more targeted than when using the more traditional oxyhydrogen flame.

Thermal cracking

With thermal cracking, the glass is exposed to localized heating, before it cracks as a result of the rapid cooling and resulting “thermal shock”. Depending on the type of glass, an initial crack may need to be introduced, which facilitates the development of the thermal shock.

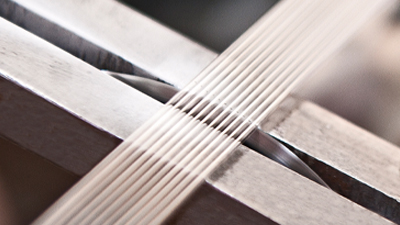

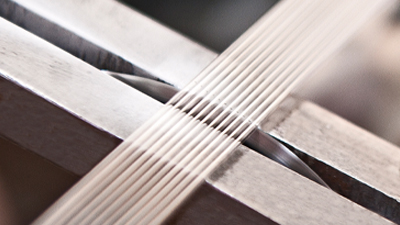

Abrasive cutting & Sawing (individually or in bulk)

For the abrasive cutting and sawing of glass, a diamond-tipped circular saw is passed through the glass. This procedure therefore makes it possible to achieve very flat cuts and maintain tight length tolerances. Abrasive cutting is particularly suitable for thick-walled tubes and capillaries, or extremely small and short sections. The cut surfaces of the parts generally have a frosted finish and may display slight chipping at the edges. Depending on the circular saw used, various cut surfaces can be created during the cutting procedure.

From glass tube blanks to sample tubes with flat bottoms and beaded rims, drawing pipettes or a tube with a kink: all these product features are achieved through the processing and forming of our various raw materials.

Hot forming with forming tools

When hot forming with tools, the glass is heated until it reaches a soft, doughy consistency. Forming tools are then used to create a profile,

for example at the end of a tube. Here, the tube is supported from the inside, while pressed into a form from the outside with the forming tool.

Various symmetrical or asymmetrical forms can be rolled on to the glass, such as collars (like the beaded rim), or even threads and flutings.

Bottom forming

There are a number of different bottoms possible: round, flat and conical bottoms, special bottoms and pedestals. Hot forming is used to shape the various designs. The glass is not initially rolled, however, but heated approximately 20 mm from the end and then drawn off from the main body. A flat bottom is created, which can be blown out with air to form a round bottom. Once the bottom is closed, it can be processed further and formed. Forming tools are used again here, for example to create a long or conical shape.

Notching, recessing & rolling

Special tools are used to form the glass in a certain position, such as a spout for measuring cylinders, or for notching a piece of glass from the wall (punching). Holes can also be made in this way. In addition to machining the edges, changes can also be made to the length of the glass tube before it is formed. For example, grooves or tapers can be rolled into the tube.

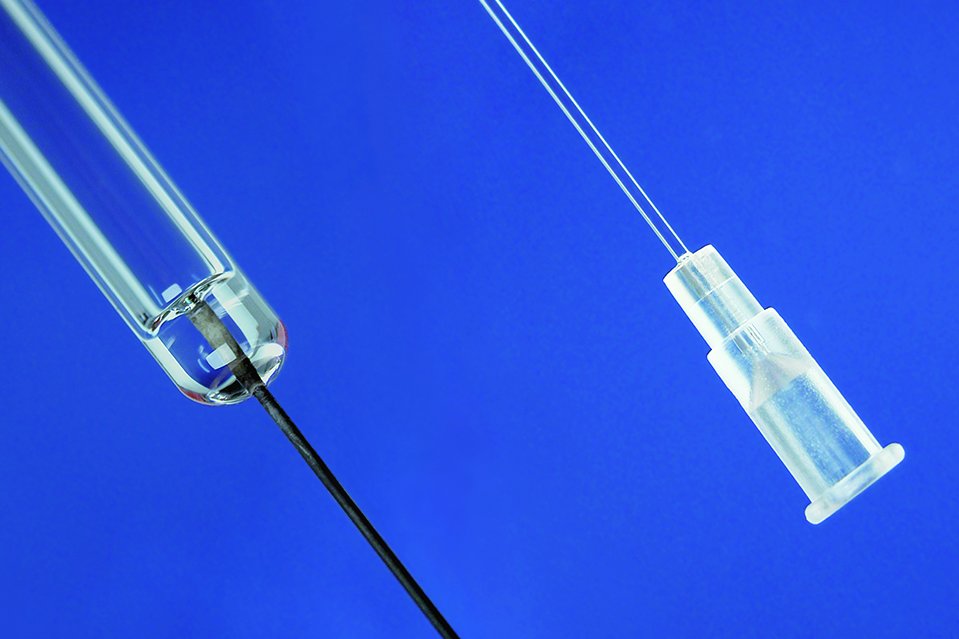

Forming of tips and outlets

Hot forming with forming tools is used to form tips with a defined outlet on larger glass tubes, as seen on graduated pipettes, for example. An internal tool is also used here to calibrate the inner channel to a certain length, while at the same time the glass is formed from the outside into a round shape on a mandrel. It is also possible to form straight outlets along short lengths of glass.

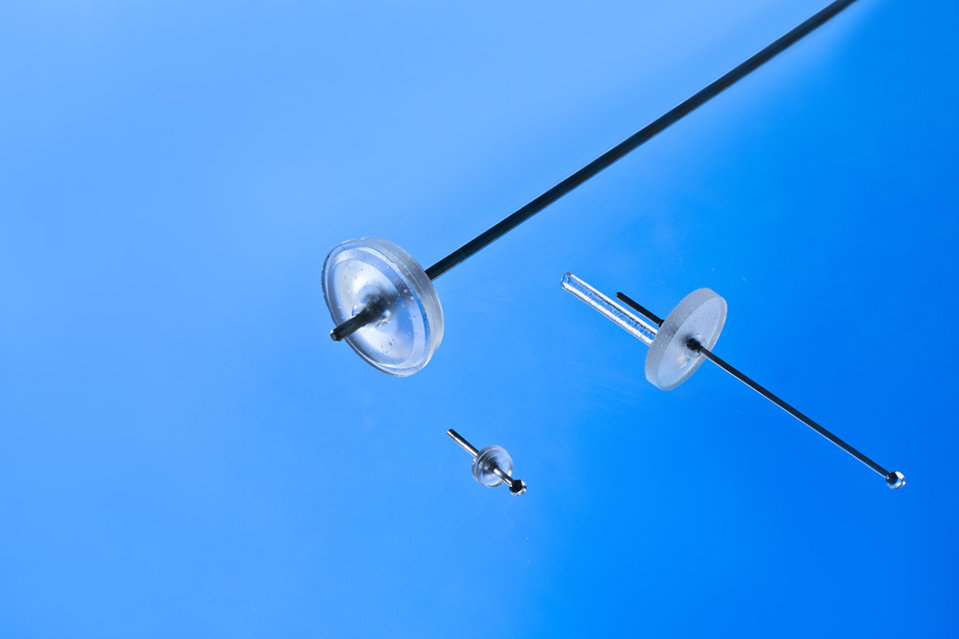

Drawing and forming of tips and microtips, nozzles

The tips of pipettes are created using a hot forming process. By heating and then drawing them out, tips of all shapes and sizes can be formed. For micropipettes, tip diameters < 1 µm are even possible.

Hot forming with forming tools

When hot forming with tools, the glass is heated until it reaches a soft, doughy consistency. Forming tools are then used to create a profile,

for example at the end of a tube. Here, the tube is supported from the inside, while pressed into a form from the outside with the forming tool.

Various symmetrical or asymmetrical forms can be rolled on to the glass, such as collars (like the beaded rim), or even threads and flutings.

Fire polishing & melting of cut edges

Fire polishing is the process used to round off ground cut edges or sharp broken edges. The cut edges are briefly subjected to an intense heat in order to melt their surface. Depending on the heat and duration of the flame, results can vary from slight to extreme rounding, or the merging of the ends which in turn involves sealing and shaping of the bottom. Fire polishing can also be used to make frosted polished edges transparent again. Or even polished surfaces on glass parts.

From glass tube blanks to sample tubes with flat bottoms and beaded rims, drawing pipettes or a tube with a kink: all these product features are achieved through the processing and forming of our various raw materials.

Bottom forming

There are a number of different bottoms possible: round, flat and conical bottoms, special bottoms and pedestals. Hot forming is used to shape the various designs. The glass is not initially rolled, however, but heated approximately 20 mm from the end and then drawn off from the main body. A flat bottom is created, which can be blown out with air to form a round bottom. Once the bottom is closed, it can be processed further and formed. Forming tools are used again here, for example to create a long or conical shape.

Notching, recessing & rolling

Special tools are used to form the glass in a certain position, such as a spout for measuring cylinders, or for notching a piece of glass from the wall (punching). Holes can also be made in this way. In addition to machining the edges, changes can also be made to the length of the glass tube before it is formed. For example, grooves or tapers can be rolled into the tube.

Forming of tips and outlets

Hot forming with forming tools is used to form tips with a defined outlet on larger glass tubes, as seen on graduated pipettes, for example. An internal tool is also used here to calibrate the inner channel to a certain length, while at the same time the glass is formed from the outside into a round shape on a mandrel. It is also possible to form straight outlets along short lengths of glass.

Drawing and forming of tips and microtips, nozzles

The tips of pipettes are created using a hot forming process. By heating and then drawing them out, tips of all shapes and sizes can be formed. For micropipettes, tip diameters < 1 µm are even possible.

Fire polishing & melting of cut edges

Fire polishing is the process used to round off ground cut edges or sharp broken edges. The cut edges are briefly subjected to an intense heat in order to melt their surface. Depending on the heat and duration of the flame, results can vary from slight to extreme rounding, or the merging of the ends which in turn involves sealing and shaping of the bottom. Fire polishing can also be used to make frosted polished edges transparent again. Or even polished surfaces on glass parts.

Forming of tips and outlets

Hot forming with forming tools is used to form tips with a defined outlet on larger glass tubes, as seen on graduated pipettes, for example. An internal tool is also used here to calibrate the inner channel to a certain length, while at the same time the glass is formed from the outside into a round shape on a mandrel. It is also possible to form straight outlets along short lengths of glass.

Drawing and forming of tips and microtips, nozzles

The tips of pipettes are created using a hot forming process. By heating and then drawing them out, tips of all shapes and sizes can be formed. For micropipettes, tip diameters < 1 µm are even possible.

Fire polishing & melting of cut edges

Fire polishing is the process used to round off ground cut edges or sharp broken edges. The cut edges are briefly subjected to an intense heat in order to melt their surface. Depending on the heat and duration of the flame, results can vary from slight to extreme rounding, or the merging of the ends which in turn involves sealing and shaping of the bottom. Fire polishing can also be used to make frosted polished edges transparent again. Or even polished surfaces on glass parts.

Fire polishing & melting of cut edges

Fire polishing is the process used to round off ground cut edges or sharp broken edges. The cut edges are briefly subjected to an intense heat in order to melt their surface. Depending on the heat and duration of the flame, results can vary from slight to extreme rounding, or the merging of the ends which in turn involves sealing and shaping of the bottom. Fire polishing can also be used to make frosted polished edges transparent again. Or even polished surfaces on glass parts.